HWACHEON HI-TECH 450CXL YMC

Hi-TECH 450 provides a rigid and stable heavy duty cutting based on a highly rigid box-way feed structure designed with an air-floating system and bed structure while maintains high precision even during long-term processing by minimizing thermal displacement Hwacheon software installed on the machine improves productivity and precision, provides better machining quality compared to existing machines.

Chuck Size: 15”

Max Turning Diameter: 21.65”

Max Turning Length: 80.31”

Bar Capacity: 4.57”

Turret Stations: 12

Y Axis: Yes

Live Tooling: Yes

Tool Presetter

Chip Conveyor

High Pressure Coolant (215PSI)

SMW Autoblock SLU3.1 Steady Rest

FANUC 0iPlus

Hwacheon Hi-TECH 230BL YSMC

The Hi-TECH 230BL YSMC provides accurate and consistent machining performance based on superior machine rigidity and upgraded specifications as compared to other 8-10″ lathes with box-way construction. In addition, the Hi-Tech 230A provides greatly enhanced operator convenience and reliability. The Y-axis model has Y-axis stroke of up to ±60mm (±2.36 inch), the largest in class

Chuck Size: 10”

Max Turning Diameter: 15.75”

Max Turning Length: 22.99”

Bar Capacity: 3.19”

Turret Stations: 12

Y Axis: Yes

Live Tooling: Yes

Sub Spindle: Yes (6” Chuck)

Tool Presetter

Chip Conveyor

Barfeeder Interface

FANUC 0iPlus

*Machine is under power and available for Demo

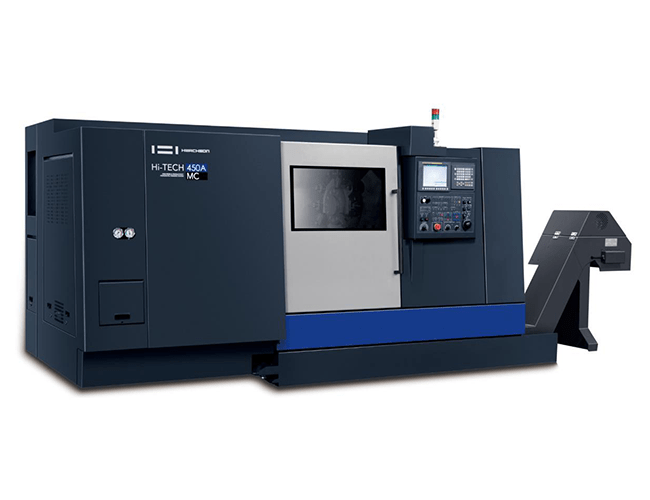

HWACHEON Hi-Tech 450BL YMC

The Hi-TECH 450BL YMC is a box way, 12″ chuck turning center with a heavy duty gearbox spindle. From basic to multi-axis turning, the Hi-TECH 450 is capable of performing a variety of the most complex production processes. The available Y-axis allows for the most complex process operations.

Chuck Size: 12”

Max Turning Diameter: 16.54”

Max Turning Length: 47.8”

Bar Capacity: 3.5”

Turret Stations: 12

Y Axis: Yes

Live Tooling: Yes

Tailstock: Yes MT#5

Tool Presetter

Chip Conveyor

Barfeeder Interface

FANUC 0iPlus

*Machine is under power and available for Demo

HWACHEON HI-TECH 200B

Customize the Hi-TECH 200B with many different spindle options to fit your work. Its small footprint and rigid box way construction will deliver quality and precision after hours of non-stop operation. The Hi-TECH 200B is a highly customizable turning center with a fast turret indexing time of 0.15sec/step and the feed-rate of 30m/min; can also be outfitted with an array of factory options. The HI-TECH 200 can handle the most demanding machining needs very efficiently.

Chuck Size: 10”

Max Turning Diameter: 13.78”

Max Turning Length: 15.16”

Bar Capacity: 2.56”

Turret Stations: 12

Y Axis: NO

Live Tooling: NO

Sub Spindle: NO

Tool Presetter

Chip Conveyor

High Pressure Coolant (215PSI)

Barfeeder Interface

FANUC 0iPlus

VM10i Plus

The Hurco VM CNC vertical milling machines offer powerful machining with a compact footprint, and absolutely the best value on the market. These CNC machining centers are the perfect combination of size and functionality. The larger work cube provides impressive X travel while not demanding excessive floor space.

26” X 16” X 20”

30” X 16” Table

12K Spindle

24 Tool Magazine

Coolant Thru Spindle

Renishaw Part Probe and Tool Setter Package

Chip Conveyor

Auxiliary Graphics Screen

Software Options:

3D Import

Swept Surface

Ultipocket

NC/Conversational Merge

Tool and Material Library

*Machine is under power and available for Demo

Hurco VMX 42Ui

The efficient design of the Hurco 5-axis trunnion table machining centers is a key benefit to consider—we use an integrated trunnion table at Hurco instead of simply sticking a trunnion table on a 3-axis machining center and passing it off as a 5-axis machine. The integrated trunnion table design provides more clearance in Z compared to other brands.

42″ x 24″ x 20.5″

Table Diameter: 15.7″

Max Weight on Table: 550 lbs

A-Axis Travel: +30°/ -110°

C-Axis Travel: 360°

12,000 rpm/ 24 hp/ 176 ft/lbs

Tool Capacity: 40

Takamaz XT6

1 Spindle, 1 Turret, Precision Lathe w/ Built-in Automation

6″ Chuck / A2-5 Spindle

12 Station Turret w/ BMT

Max Turning Dia: 200mm

Max Turning Length: 240mm

Tailstock – MT#3

Compact Footprint w/ built in infeed/outfeed conveyor and gantry robot loader

We can take your surplus machinery in on trade, broker it or buy. Contact us to learn more about your options.